"atfsgeoff" (atfsgeoff)

"atfsgeoff" (atfsgeoff)

03/17/2019 at 23:00 ē Filed to: None

3

3

14

14

"atfsgeoff" (atfsgeoff)

"atfsgeoff" (atfsgeoff)

03/17/2019 at 23:00 ē Filed to: None |  3 3

|  14 14 |

How common is this kind of setup?

gmporschenut also a fan of hondas

> atfsgeoff

gmporschenut also a fan of hondas

> atfsgeoff

03/17/2019 at 23:14 |

|

thats a new one. how do you compress the piston rings to get them in?

Full of the sound of the Gran Fury, signifying nothing.

> atfsgeoff

Full of the sound of the Gran Fury, signifying nothing.

> atfsgeoff

03/17/2019 at 23:24 |

|

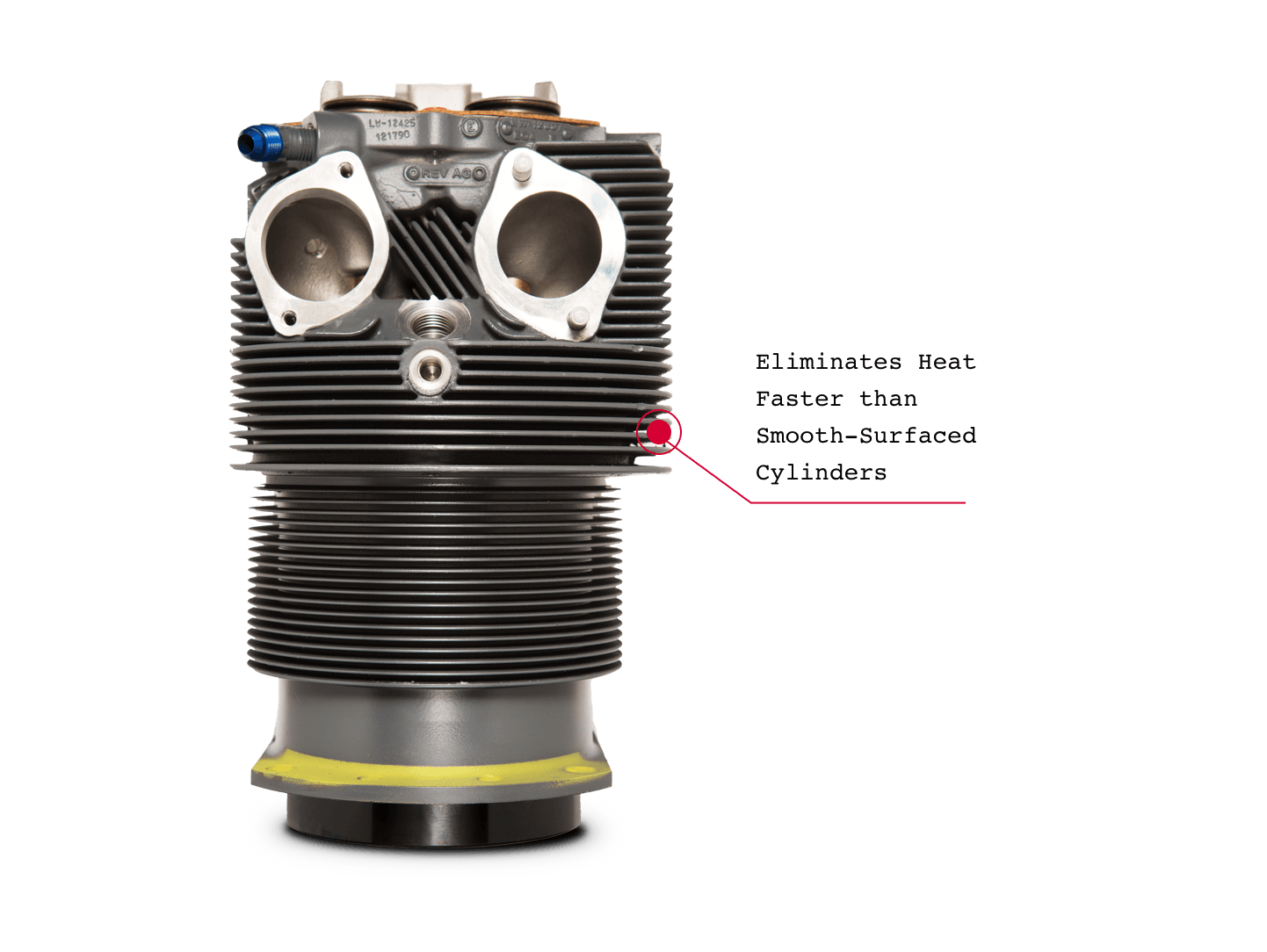

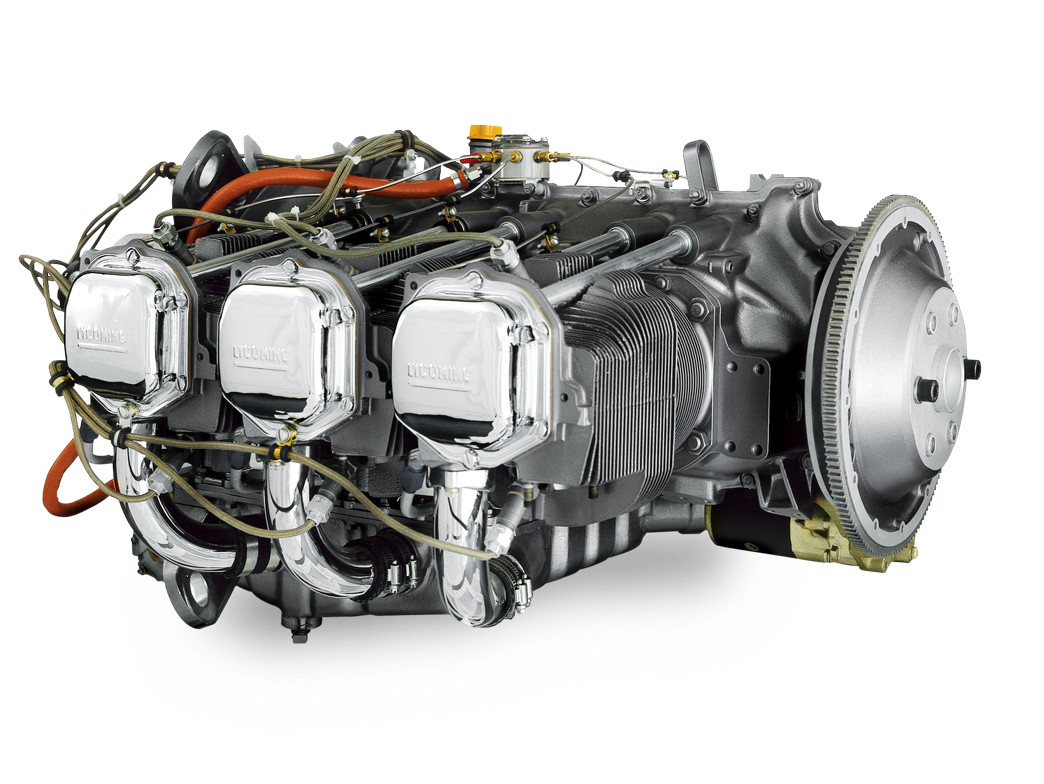

I guess it depends on what kind of engine youíre talking about. In aviation itís incredibly common.

Alfalfa

> Full of the sound of the Gran Fury, signifying nothing.

Alfalfa

> Full of the sound of the Gran Fury, signifying nothing.

03/17/2019 at 23:28 |

|

Th emoreyouknow.gif

atfsgeoff

> Full of the sound of the Gran Fury, signifying nothing.

atfsgeoff

> Full of the sound of the Gran Fury, signifying nothing.

03/17/2019 at 23:35 |

|

Yeah I guess thatís similar in principle, and Iíve seen lots of pre-war engine designs which use individual cylinders kind of bolted onto a shared crankcase, but theyíre almost invariably pushrod designs; Iíve never seen

an overhead-cam cylinder head with the cylinder walls molded into it like this.

atfsgeoff

> gmporschenut also a fan of hondas

atfsgeoff

> gmporschenut also a fan of hondas

03/17/2019 at 23:36 |

|

Good question, I legitimately donít know. This motor is scrap so I donít intend on rebuilding it to function

, maybe Iíll run some experiments later.

gogmorgo - rowing gears in a Grand Cherokee

> atfsgeoff

gogmorgo - rowing gears in a Grand Cherokee

> atfsgeoff

03/18/2019 at 01:37 |

|

Thatís... interesting. I donít see any real reason why it wouldnít work, except itís looking like those are super thin walls and clearly a liquid cooled engine, and Iím not sure where youíd run the cooling passages. I have a hard time believing theyíd be able to get proper seals at the same time at both the head gasket and bottom of the sleeves to keep coolant out of the crankcase... Unless this design means you donít need as serious of a head gasket because the piston† rings are doing the job? Maybe that's an advantage to this... but it still seems like it's more bothersome than it needs to be.†

pip bip - choose Corrour

> atfsgeoff

pip bip - choose Corrour

> atfsgeoff

03/18/2019 at 04:27 |

|

never seen by me before

whatís it out of?

You can tell a Finn but you can't tell him much

> Full of the sound of the Gran Fury, signifying nothing.

You can tell a Finn but you can't tell him much

> Full of the sound of the Gran Fury, signifying nothing.

03/18/2019 at 09:10 |

|

Are the head and cylinder a single piece on those?† I always assumed the head bolted to the cylinder while the cylinder bolted to the crankcase.

Pickup_man

> gmporschenut also a fan of hondas

Pickup_man

> gmporschenut also a fan of hondas

03/18/2019 at 09:21 |

|

Similar to most motorcycle engines Iíve seen the bottom of the cylinder has a section of taper to it. You drop the cylinder down on top of the piston, and compress each ring one at a time. I usually compress them by hand, or lightly press them in with a screwdriver.

atfsgeoff

> gogmorgo - rowing gears in a Grand Cherokee

atfsgeoff

> gogmorgo - rowing gears in a Grand Cherokee

03/18/2019 at 09:25 |

|

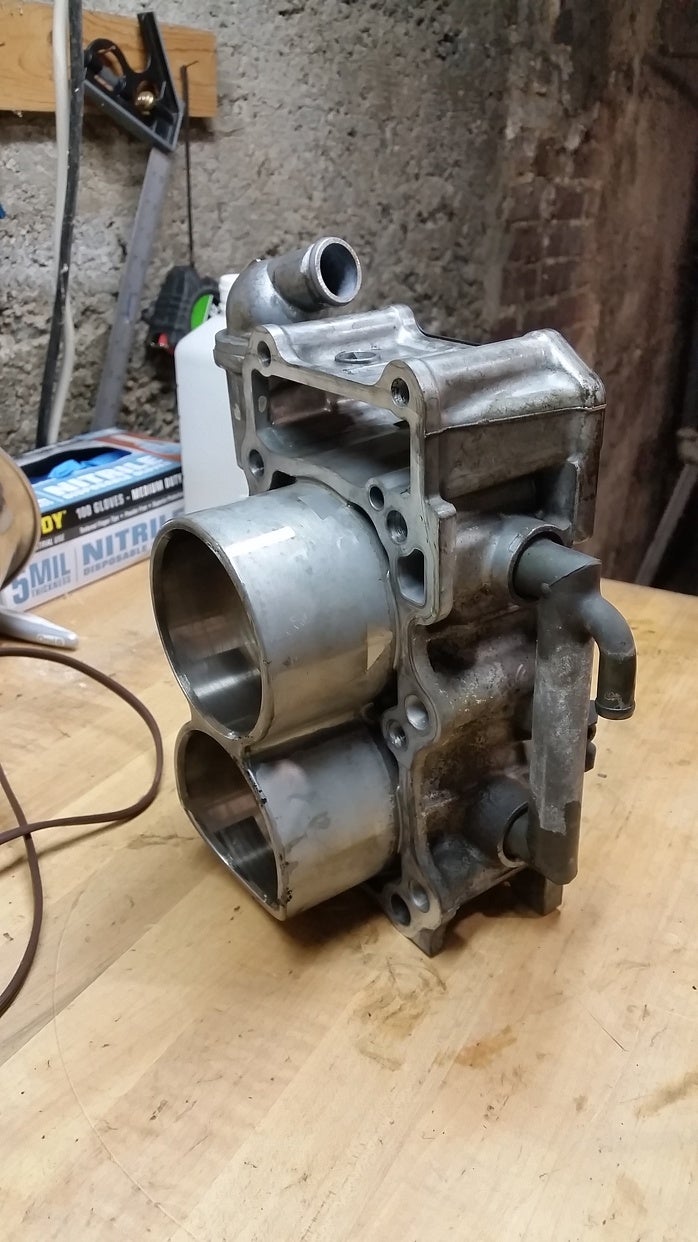

A pparently I was missing a seam. Turns out the cylinder walls are their own separate section (??):

Full of the sound of the Gran Fury, signifying nothing.

> You can tell a Finn but you can't tell him much

Full of the sound of the Gran Fury, signifying nothing.

> You can tell a Finn but you can't tell him much

03/18/2019 at 17:07 |

|

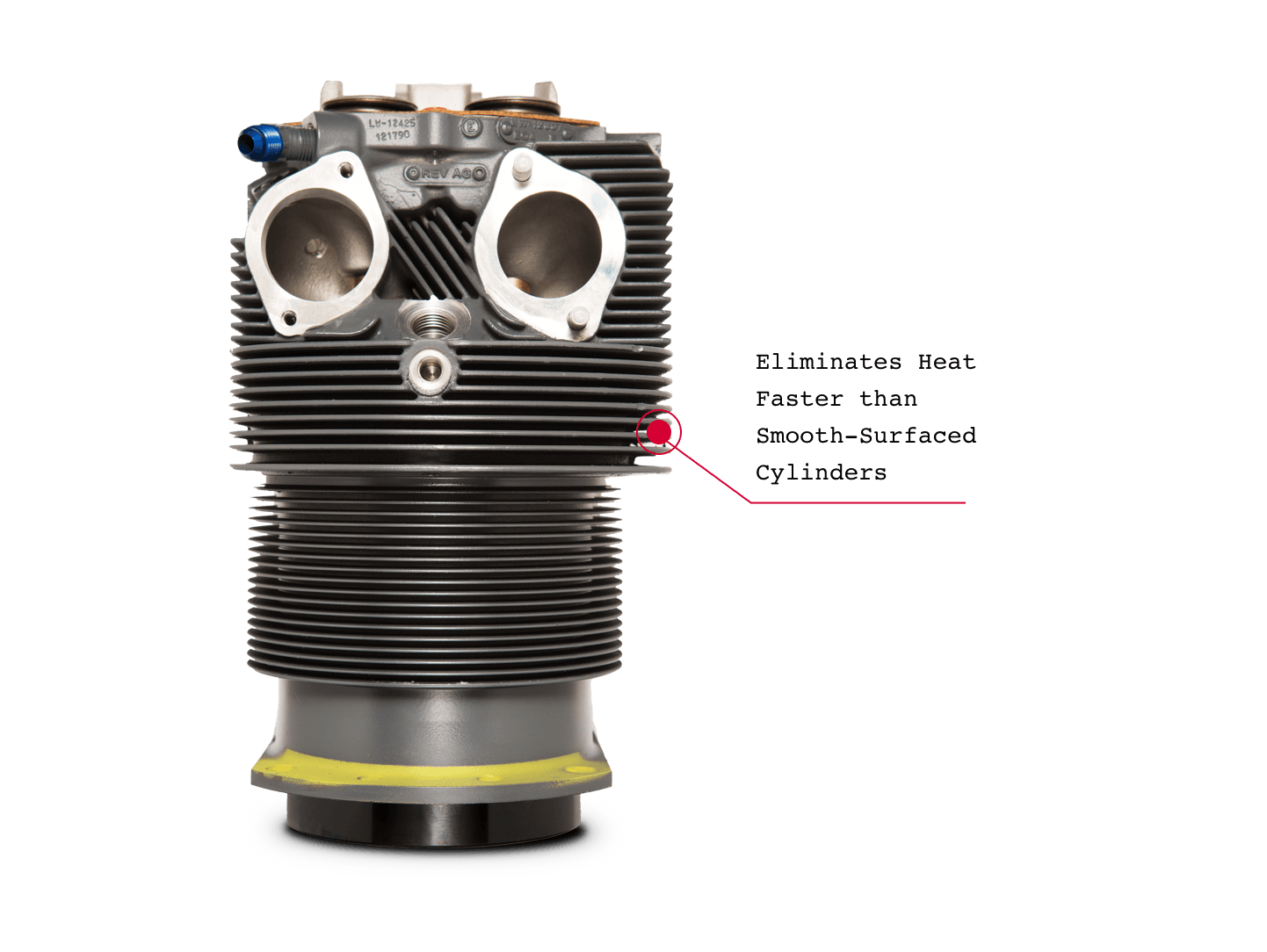

Yes, the cylinder barrel and head are one integrated casting - no head gasket necessary since there isn't a separation between the two where compression could leak out. Not that it doesn't, it just finds other ways out...

gogmorgo - rowing gears in a Grand Cherokee

> atfsgeoff

gogmorgo - rowing gears in a Grand Cherokee

> atfsgeoff

03/18/2019 at 20:30 |

|

Well that's certainly interesting. How are they retained? Are they really just sandwiched between the head and block?

gogmorgo - rowing gears in a Grand Cherokee

> gogmorgo - rowing gears in a Grand Cherokee

gogmorgo - rowing gears in a Grand Cherokee

> gogmorgo - rowing gears in a Grand Cherokee

03/18/2019 at 20:35 |

|

Or wait. No. Youíve got a split block, and youíve separated the two pieces instead of just pulling the head, and now youíve got the head off. Itís more common on bikes, sleds, and similar smaller engines I think than automotive applications, but itís still a thing. It gives you the option to replace cylinder walls without machining the old parts, getting new p istons, etc.

atfsgeoff

> gogmorgo - rowing gears in a Grand Cherokee

atfsgeoff

> gogmorgo - rowing gears in a Grand Cherokee

03/18/2019 at 21:45 |

|

In this particular application, the cylinder walls were retained only by the head bolts. That part came off along with the head as one piece, with nothing but the gasket holding it to the head.